Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: PRO-CLEAN Barrel Cooling Channels Cleaning Machine

Brand: PROMAXX

Status: New

Screw Design: Double-Screw

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Germany, South Korea, Japan

Place Of Origin: China

Core Selling Point: Competitive Price

Applicable Industry: Manufacturing Plant, Machinery Repair Shops

Marketing Type: Other

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Packaging: Wooden pallet / Carton / Shrink

Productivity: 50000pcs screw elements/Year

Transportation: Ocean,Land,Air,Express

Place of Origin: CHINA

Supply Ability: 50000pcs screw elements/Year

Certificate: ISO9001

HS Code: 8477904501

Port: JIANGMEN,GUANGZHOU,SHENZHEN

Payment Type: T/T

Incoterm: EXW

PRO-CLEAN Barrel Cooling Channels Cleaning Machine

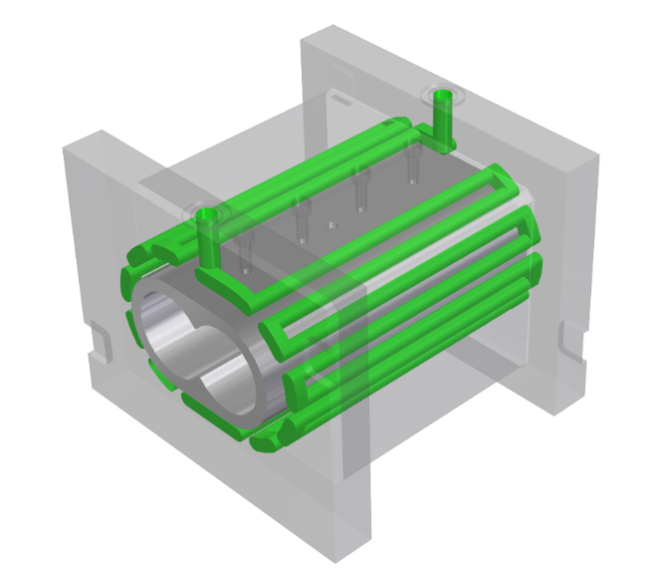

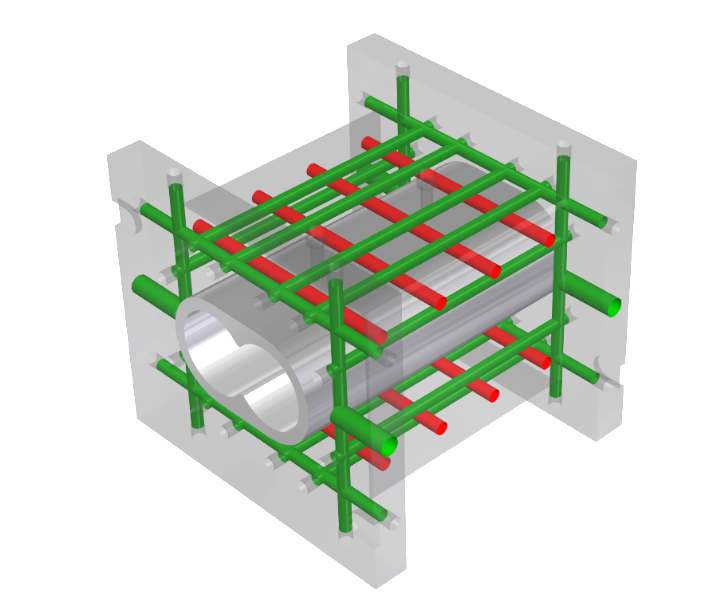

►Equipment composition: water channel cleaning host, pipeline, joint, high-precision flowmeter

►Software system: Pro-Clean PLC control system

►Performance characteristics:

●No need to disassemble the barrel, and the water channel capacity, flow and leakage of the

whole Extruder Barrel are detected online

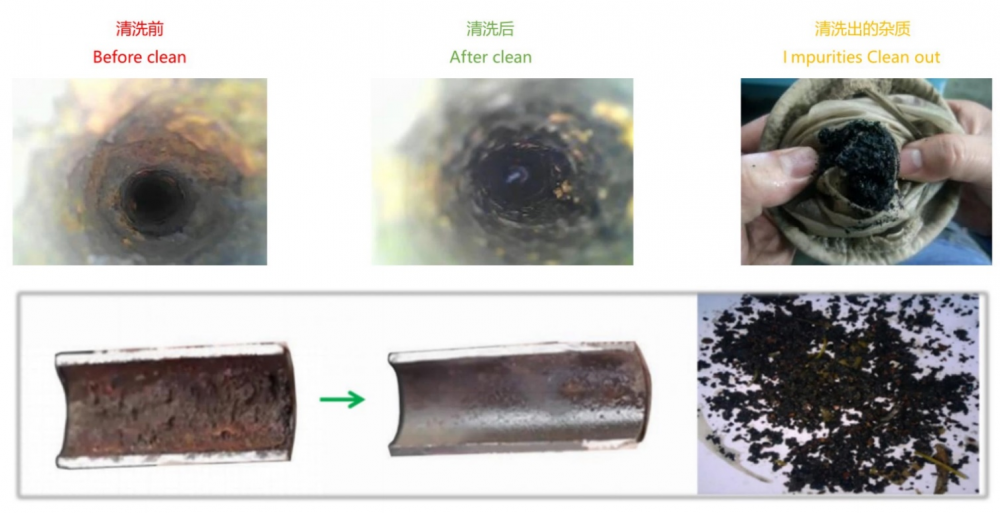

●Extruder users can regularly clean and dredge the water channels inside barrels without damage,

so as to effectively avoid water channel blockage and maintain the temperature control accuracy

of the barrel

●Operation is simple, convenient, and efficient. Four barrels can be cleaned at once

●Environmental friendly solvent is adopted. The solvent will not damage the inner wall of the water

channel of the barrel and pollute the environment

●A test report will be generated to record condition and cleaning effect of cooling channels

CNC Horizontal Milling Machine 290kg

Basic Parameters

1600x500x1200mm(L*W*H)

Total weight

Overall dimensions

AC 380V/50HZ

Power

2.5KW

Water tank

100 liters Electricity supply

0.2-0.5MPa

Pipe connection

DN25/DN10

Inlet/Outlet

4 in/4 out Water pressure

0.6-0.9MPa

Filters

2 sets

Solvent

Neutral Air pressure

Mitsubichi

Electrical part

Schneider

Pump brand

SMC

| Components | ||

| No. | Part/Unit | Amount |

| 1 | Cleaning machine | 1 unit |

| 2 | Pipes and connections | 20 sets |

| 3 | Neutral solvent(500g/bottle) | 30 bottles |

| 4 | Precise flow meter | 4 pcs |

Applications:

●Daily inspection and maintenance of cooling

channels of Twin Screw Extruder

●Daily inspection and maintenance of cooling

channels of single screw extruder

●Inspection, maintenance and dredging of cooling channels and hot runner of injection molding machines

and plastic moulds

INTRODUCTION

PromaXX is an expert in Twin-screw Extruder Spare Parts manufacturing.

We are capable of producing Extruder Screw Elements, Extruder Barrel, Extruder Shaft and Accessories.

SUPPLY ABILITY & ADDITIONAL INFORMATION

Supply Ability:

50000 pcs of screw elements Per year

1000 pcs of new barrels Per year

1000 pcs of high torque shafts and accessories Per year

Payment Type:

EX WORKS,T/T, Alibaba shop credit

Certificate:

ISO9001

ABOUT US

We are a Sino-German joint venture founded in 2015. Adopted with sophisticated

management and European manufacturing technology, PromaXX has won prestige

and reputation in globle market for its top quality products and professional services.

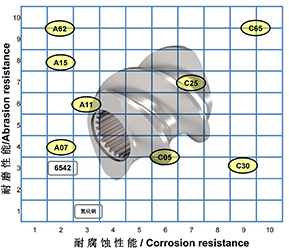

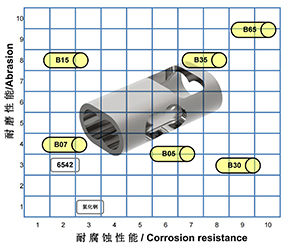

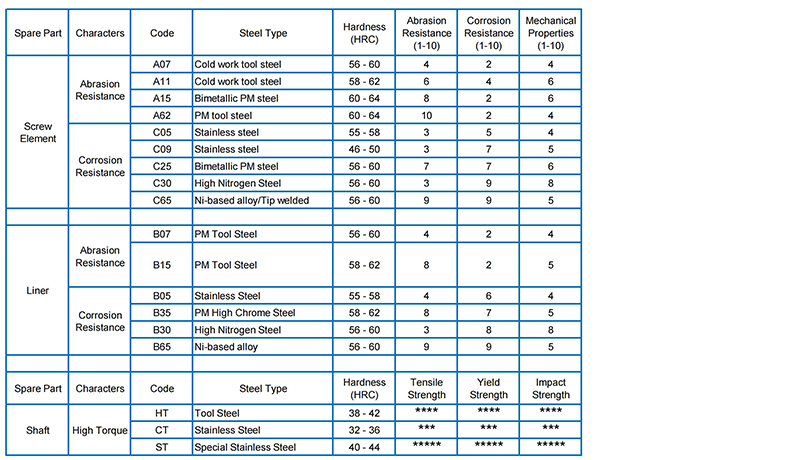

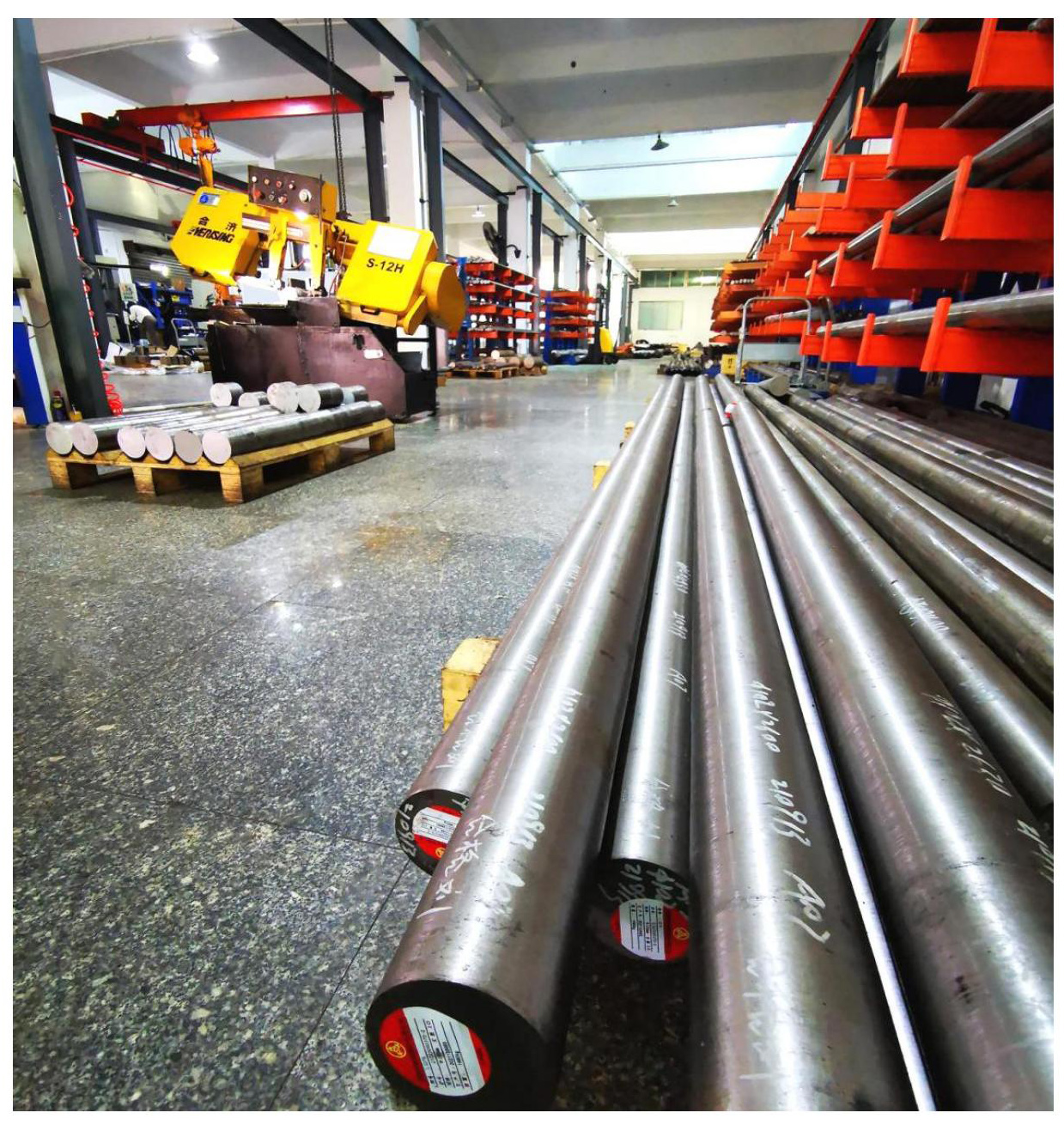

MATERIAL

European steel grades:

►Cold-working tool steels, martensite stainless steels

►PM-HIP tool steels,HSS

►Ni-based alloys, Co-based alloys

IQC of raw material:

►Chemical analysis

►Microstructure inspection

►Material certificate

►Certificate of Origin

Professional heat treatment

PROCESSING EQUIPMENT

| EQUIPMENT | QTY |

| 3D Coordinate Measurer | 1 |

| CNC Horizontal Milling Machine | 2 |

| 4-axis CNC Milling Machine | 8 |

| CNC Milling Machine | 8 |

| CNC Lathe | 6 |

| CNC Screw Lathe | 8 |

| Conventional Lathe | 2 |

| CNC Flat Grinder | 4 |

| CNC Cylinderical Grinder | 4 |

| Wire EDM | 16 |

| Sink EDM | 4 |

| Broaching Machine | 1 |

| Honing Machine | 2 |

| Laser Making Machine | 2 |

APPLICATION

CONTACT US

Product Categories : Extruder maintenance equipment > PRO-CLEAN Barrel Cooling Channels Cleaning Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.